Services

SPRAY DRYING

Spray drying produces engineered powders from liquid feeds in a single step. The liquid feed, which may contain solids that are dissolved, in suspension, or combination thereof, is atomized into the drying chamber. In the chamber the droplets interact with hot drying gas causing their moisture to evaporate resulting in solid particles. Once dry, the particles are extracted from the process gas via cyclone (inertial separator) or filtration. Subsequent environmental conditioning of powders (control of residual moisture) and packaging can be accomplished in our isolator.

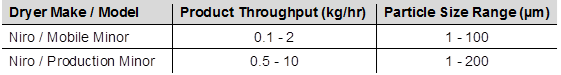

Equipment and Capabilities:

It has been said that the particle party starts with the atomizer. For this reason, Flurry Powders offers a range of atomization approaches: Hydraulic (pressurized liquid), twin fluid (liquid & gas), and ultrasonic (low shear).